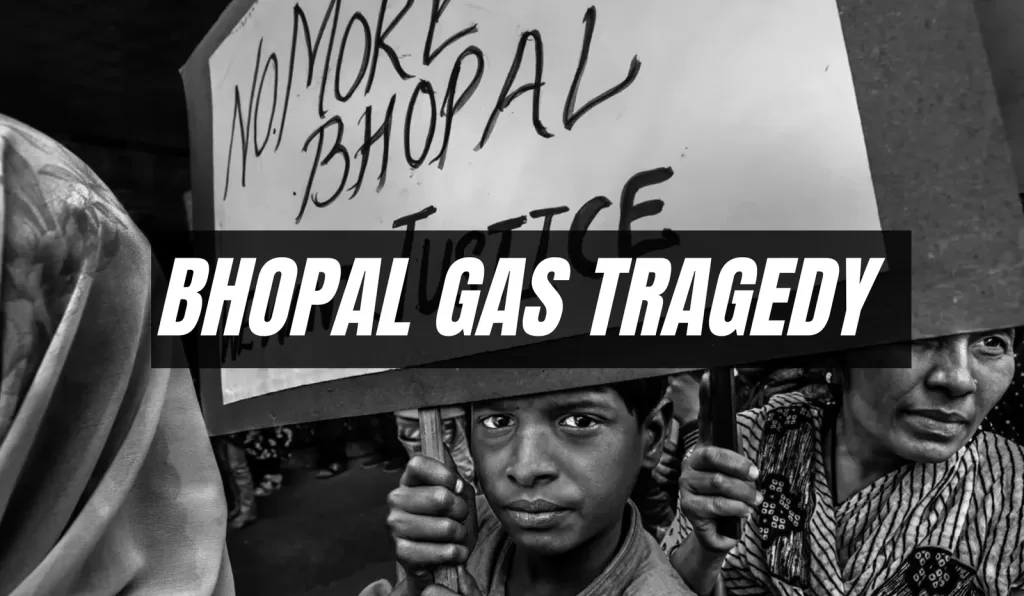

Introduction: Bhopal Gas Tragedy

The Bhopal Gas Tragedy, one of the most devastating industrial disasters in history, left an indelible mark on the world’s collective memory. On the night of December 2, 1984, a deadly cloud of methyl isocyanate gas leaked from a pesticide plant in Bhopal, India, exposing over 500,000 people to toxic fumes. The disaster claimed the lives of thousands, and many more continue to suffer from its long-term effects. In the aftermath, the world learned hard-hitting lessons about industrial safety, disaster preparedness, corporate responsibility, and the need for stronger regulations.

The impact of the Bhopal Gas Tragedy continues to shape global safety standards and policymaking, underscoring the importance of robust preventive measures in industrial practices. This article delves into the lessons learned from the tragedy, examining the pivotal changes in industrial safety practices, legislative reforms, and the evolution of disaster response strategies.

The Tragedy That Shook the World

On that fateful night, the Union Carbide India Limited (UCIL) plant in Bhopal released an enormous amount of toxic gas, causing widespread panic and chaos. Thousands of people died within hours due to gas inhalation, and many more succumbed to long-term illnesses, including respiratory diseases, eye problems, and neurological damage. The tragedy has left a lasting impact on the city of Bhopal, where survivors and their descendants continue to suffer.

The immediate causes of the disaster were poor safety protocols, inadequate training, and malfunctioning safety systems. But the root cause went beyond these technical failures. It was a combination of negligence, lack of corporate accountability, and the absence of stringent regulations that led to the catastrophe. These failures exposed significant vulnerabilities in the global industrial safety framework and called for urgent reforms.

Lessons Learned for Industrial Safety

1. The Importance of Strict Safety Standards

The Bhopal Gas Tragedy revealed that even small lapses in safety measures can have catastrophic consequences. One of the most important lessons from the tragedy is the need for strict adherence to safety standards and protocols. Companies must prioritize the safety of their workers and the surrounding community above all else. In the wake of Bhopal, industrial safety standards worldwide became more stringent, with organizations adopting best practices like regular safety drills, risk assessments, and the installation of redundant safety systems to prevent accidents.

2. Risk Assessment and Management: A Vital Tool

Prior to the Bhopal disaster, many industrial plants, especially in developing countries, failed to carry out comprehensive risk assessments. Risk management involves identifying potential hazards, evaluating their likelihood, and implementing strategies to mitigate these risks. The Bhopal tragedy highlighted the critical importance of such assessments in industrial settings. Today, risk management is integral to any industrial operation, with regular audits and contingency plans being mandatory in most industries.

3. Emergency Response and Disaster Preparedness

Another key lesson learned from Bhopal is the necessity of having a robust emergency response system in place. The lack of an adequate response system in Bhopal delayed the evacuation efforts and exacerbated the damage. Now, industries are required to have clear emergency response plans that are regularly tested and updated. Additionally, local governments and industrial plants must collaborate to ensure that first responders are properly trained and equipped to handle such crises.

The Role of Policymaking: Strengthening Regulatory Frameworks

4. Strengthening Regulatory Oversight

Before the Bhopal Gas Tragedy, regulatory bodies often failed to ensure that companies adhered to safety standards. Following the disaster, governments around the world recognized the need for stronger regulatory oversight. In India, the Bhopal disaster led to the establishment of the Environment Protection Act of 1986, aimed at ensuring the protection of the environment and public health. Globally, similar reforms were adopted, and international conventions, such as the Seveso Directive in the European Union, were introduced to regulate high-risk industries.

5. Corporate Accountability and Transparency

One of the most contentious issues following the Bhopal disaster was the question of corporate accountability. Union Carbide’s slow response to the disaster, coupled with its reluctance to take full responsibility for the catastrophe, sparked widespread outrage. This led to global calls for holding corporations accountable for their actions, especially when they endanger public health and safety. In response, many countries implemented laws requiring greater transparency from corporations, including full disclosure of risk assessments and regular safety audits.

6. The Need for International Collaboration

The Bhopal Gas Tragedy highlighted the importance of international collaboration on industrial safety. While the disaster occurred in India, it had far-reaching effects across the globe. The tragedy underscored the need for multinational corporations to adhere to the highest safety standards, regardless of the country in which they operate. International organizations, such as the United Nations, have since advocated for the development of global safety standards and protocols that ensure consistent industrial safety across borders.

Timeline of the Bhopal Gas Tragedy

December 2, 1984 – The toxic gas leak at the Union Carbide plant in Bhopal occurs, releasing an estimated 42 tons of methyl isocyanate gas into the atmosphere. The leak lasts for several hours, and thousands of people are affected.

December 3, 1984 – The Indian government begins emergency relief operations, and medical teams are deployed to treat the victims. The initial reports estimate the death toll to be around 2,000, but this number grows significantly over the following weeks.

December 1984 to March 1985 – Union Carbide sets up a temporary relief fund for the victims, but the compensation offered is seen as grossly inadequate. Survivors continue to suffer from long-term health problems.

1986 – The Indian government passes the Environment Protection Act to strengthen safety standards and environmental regulations in response to the Bhopal disaster.

2001 – Union Carbide’s former CEO, Warren Anderson, is charged with manslaughter in India but never extradited. The legal battle over compensation and accountability continues for decades.

2024 – The Bhopal Gas Tragedy remains a critical case study in industrial safety, and the survivors continue their fight for justice.

Expert Opinions on the Lessons from Bhopal

Many safety experts and environmentalists have spoken about the lessons learned from the Bhopal Gas Tragedy. Dr. Vandana Shiva, a prominent environmental activist, has argued that the tragedy highlights the dangers of unregulated industrial growth and calls for stricter environmental laws. She advocates for local community involvement in industrial decision-making to ensure that safety is prioritized.

Dr. R. K. Srivastava, a safety expert with over three decades of experience, has emphasized the importance of comprehensive safety audits and the need for continuous monitoring of high-risk industrial processes. He believes that industries must adopt a culture of safety and prioritize the well-being of the community.

Dr. Anupam S. Jha, a disaster management specialist, has stated that the Bhopal disaster demonstrated the critical need for a strong legal framework that holds companies responsible for their negligence. He suggests that legal reforms should focus on enforcing stricter penalties for non-compliance with safety standards.

Conclusion: A Wake-Up Call for Industrial Safety

The Bhopal Gas Tragedy was a wake-up call for the world. It underscored the need for stricter industrial safety standards, more robust regulatory frameworks, and a corporate culture of accountability. While the tragedy’s lessons have led to significant improvements in safety protocols and policies, the fight for justice for the survivors continues. Moving forward, it is crucial that both governments and corporations take proactive steps to prevent such disasters from ever happening again. The Bhopal Gas Tragedy will forever serve as a stark reminder of the importance of industrial safety, the need for transparency, and the imperative of protecting both workers and the surrounding communities.

Take Your Trading And Financial Skills to the Next Level!

Take Your Trading And Financial Skills to the Next Level!

If you enjoyed this post, dive deeper with our Profitable Trader Series—a step-by-step guide to mastering the stock market.

- Stock Market 101: Profits with Candlesticks

- Stock Market 201: Profits with Chart Patterns

- Stock Market 301: Advanced Trade Sheets

Start your journey now!

For Regular News and Updates Follow – Sentinel eGazette

FAQs:

Q1: What was the main cause of the Bhopal Gas Tragedy?

- The Bhopal Gas Tragedy was primarily caused by the leak of methyl isocyanate gas from the Union Carbide pesticide plant. Poor safety protocols, maintenance issues, and lack of effective emergency systems contributed significantly to the disaster.

Q2: How many people died in the Bhopal Gas Tragedy?

- Initial estimates reported around 2,000 deaths, but the long-term health effects caused thousands more deaths. By 2006, official figures indicated more than 15,000 fatalities, with over half a million people exposed to toxic gas.

Q3: How did the Indian government respond to the Bhopal tragedy?

- The Indian government initiated emergency relief efforts, providing medical treatment, and compensating the victims. However, it was criticized for its delayed response and the inadequate compensation given to survivors. Legal proceedings and attempts for accountability against Union Carbide followed.

Q4: What changes in industrial safety emerged after the Bhopal disaster?

- After Bhopal, there was a significant overhaul in industrial safety standards worldwide. Countries adopted stricter safety regulations, mandatory risk assessments, emergency response systems, and better corporate transparency regarding safety audits.

Q5: What is the legal status of Union Carbide and its executives after Bhopal?

- Union Carbide faced legal action, but Warren Anderson, the CEO at the time, was never extradited. Union Carbide was bought by Dow Chemical in 2001, and the legal battle over compensation for the victims continued for decades.